The Critical Role of Spare Parts and Lifecycle Management

The Problem

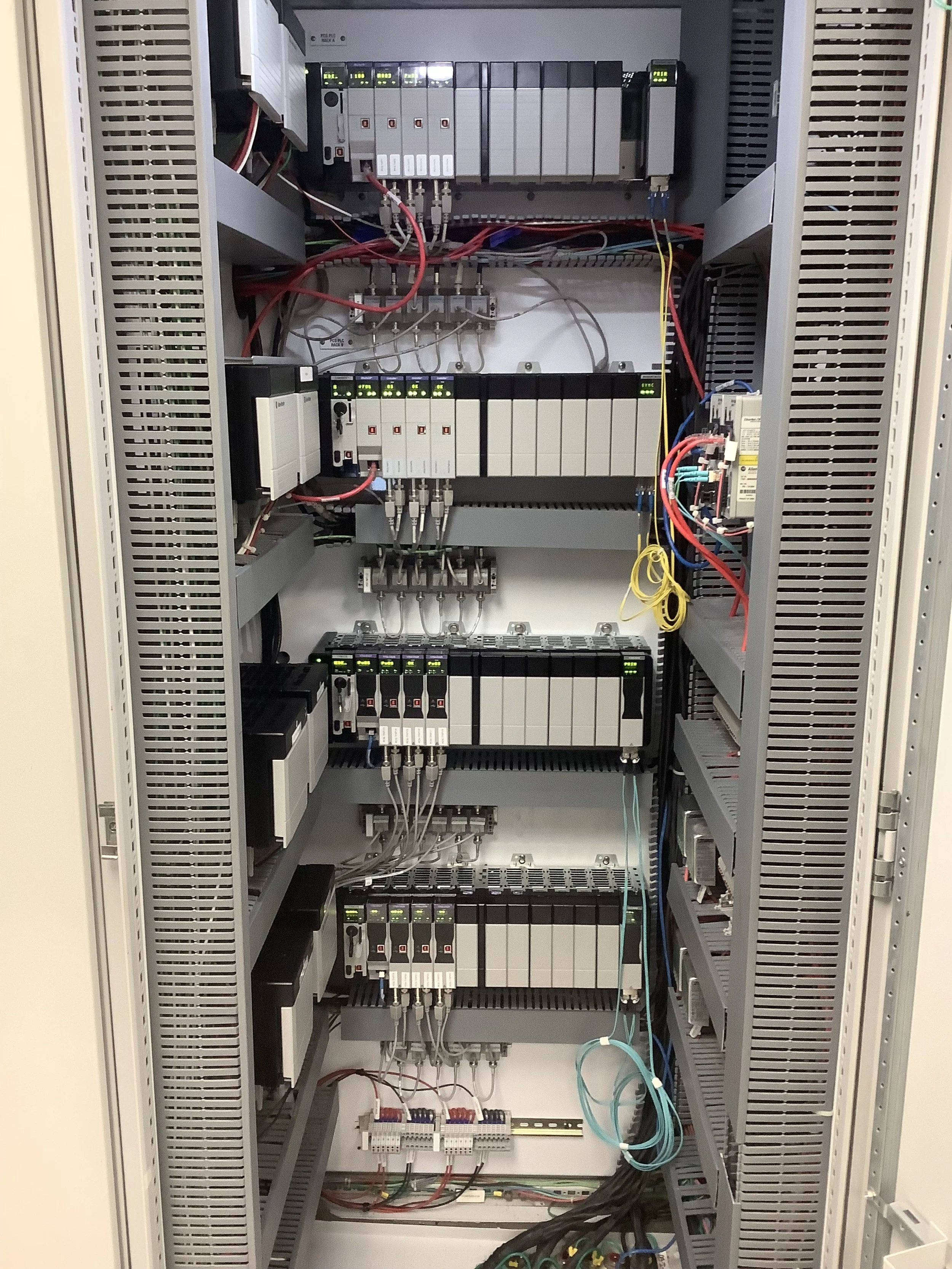

There are two major components to calculating the availability of a control system: mean time to fail (MTTF) and mean time to repair (MTTR). At a system level, MTTF is determined by the chosen control strategy and redundancy, while MTTR is determined by the time it takes to detect the failure problem, added to the time to replace the failed component with a replacement card and to bring the system back up and running.

Since system failure is inevitable, having access to the right replacement parts is fundamental to maintaining continuous operations in the plant. It is imperative that MTTR has to be minimized.

The Consequence

The lack of adequate spare parts for remotely located plants can have severe economic and safety consequences. Besides the obvious financial loss due to production standstill, there may also be implications to the safety of the plant, e.g., voting systems on gas detectors need to function at all times to help safeguard local personnel.

The Cause

x New builds: purchasing spares can be a low priority when new systems are installed, as the focus is generally on commissioning the plant. It is also difficult to gauge exactly which cards are likely to fail and in what quantities they will fail. Failing to address these issues leads to a lack of physical spares when most needed.

x Plants in service for a long time: the problem we see most often is that system obsolescence makes it difficult to source cards. There is an additional challenge at the HMI level in that PCs and servers that run the HMI software also have a limited lifespan. From time to time, we’re contacted to provide replacement

PCs and servers, only to find that the latest generation of PCs and servers are no longer able to run old operating systems such as Windows XP. In these cases, the systems may have to run in a compromised mode for some time until we can upgrade the systems to the latest operating system version.

The Solution

Having adequate spares available requires regular review of both the existing spares holdings and the life cycle of the control system, and that means:

✓ Reviewing spares holding regularly when your system maintenance teams perform site audits.

✓ Using experts with experience to help determine the appropriate replacement parts and quantities to hold on-site.

✓ Sharing best practices across customer bases - issues at one plant help to indicate what is likely to occur at other similar sites.

✓ Understanding where in the life cycle a particular control system is so that a plan for upgrades and migrations can be strategized and devised well in advance.

Discover how our integrated services can elevate your projects.

With a rich legacy of experience, we prioritize risk reduction, safety, quality, and innovation.

Ensuring seamless project execution from concept through project completion.